DOI: 10.1038/s41598-020-80114-6

- 1. Division of Molecular Science, Faculty of Science and Technology, Gunma University

- 2. Gunma University Center for Food Science and Wellness

- 3. Spiber Inc.

From “Environmental biodegradability of recombinant structural protein” by Yuya Tachibana et al.. Licensed under CC-BY 4.0.

Abstract

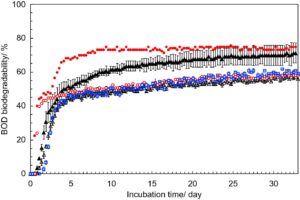

Next generation polymers needs to be produced from renewable sources and to be converted into inorganic compounds in the natural environment at the end of life. Recombinant structural protein is a promising alternative to conventional engineering plastics due to its good thermal and mechanical properties, its production from biomass, and its potential for biodegradability. Herein, we measured the thermal and mechanical properties of the recombinant structural protein BP1 and evaluated its biodegradability. Because the thermal degradation occurs above 250 °C and the glass transition temperature is 185 °C, BP1 can be molded into sheets by a manual hot press at 150 °C and 83 MPa. The flexural strength and modulus of BP1 were 115 ± 6 MPa and 7.38 ± 0.03 GPa. These properties are superior to those of commercially available biodegradable polymers. The biodegradability of BP1 was carefully evaluated. BP1 was shown to be efficiently hydrolyzed by some isolated bacterial strains in a dispersed state. Furthermore, it was readily hydrolyzed from the solid state by three isolated proteases. The mineralization was evaluated by the biochemical oxygen demand (BOD)-biodegradation testing with soil inocula. The BOD biodegradability of BP1 was 70.2 ± 6.0 after 33 days.